Greddy E Manage Blue Wiring Manual

Today we’ll be looking at Greddy’s Emanage unit and how to install it on a 2001 Acura Integra. This Greddy “blue box” is a much maligned but still very useful tuning tool that has powered many a import into the 500+ hp range. Often confused with the units sold with the Greddy 50 state legal turbo kits of their era, this is the real Greddy Emanage we’ll be installing today. Walkthrough 1: Install and Operation – Today’s How To Walkthrough 2: Operating and Learning about your Greddy Emanage Manual: Greddy’s piggyback fuel and timing computer is exactly what the doctor ordered for obdii vehicles who are challenged with timing issues. The install of the Emanage unit should be something that is performed by an experienced tuner or expert mechanic ONLY! We are not responsible for any damage to your application!! Tools needed:.

Greddy E Manage Wiring E manage greddy, for e manage ultimate support please email this completed pdf form to tech@greddycom: e manage ultimate installation manual. Greddy E-manage User Manual. User manual, wiring. Greddy Emanage Blue - Anyone like tuning them - Sydney - posted in Dyno and Tuning: Guys, Does anyone know a. The comprehensive guide on How To Install a Greddy Emanage. My Pro Street. GReddy e-Manage Manual. Greddy’s piggyback fuel and timing computer is.

Wire Strippers or scissors. Pliers. 10 mm socket and handle.

E Manage Blue

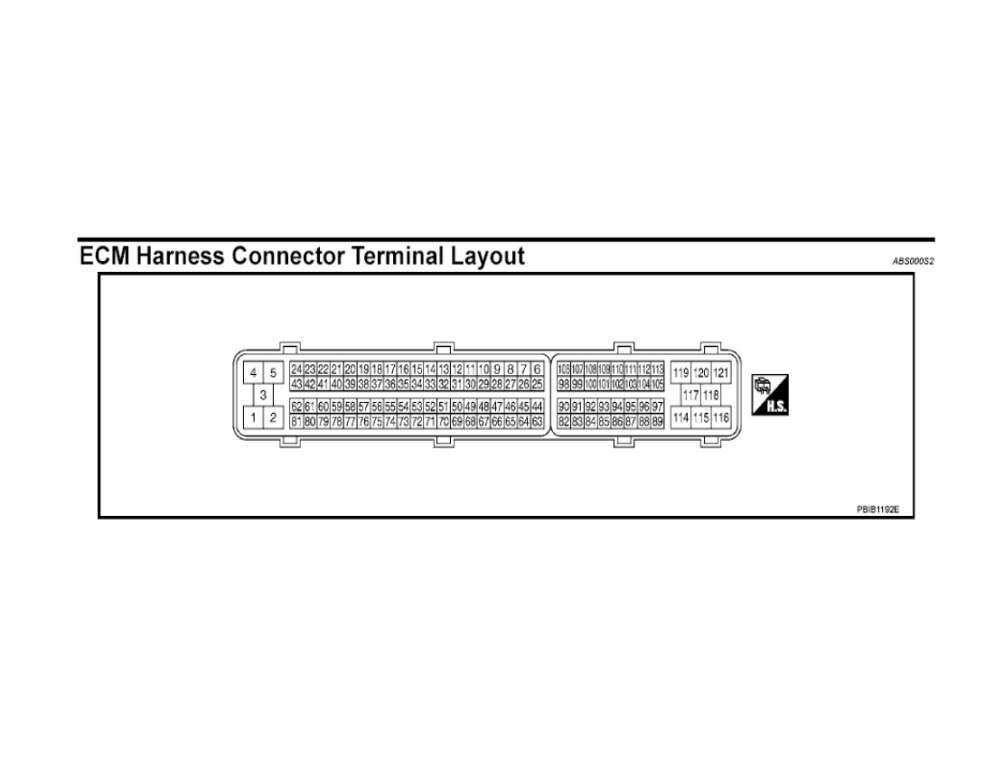

Soldering Iron The Emanage unit is accompanied with all the hardware necessary for the install. Please study the ECU pinouts before beginning. First start by sliding your passenger seat as far back as possible to allow you the space to operate. In our test vehicle, this 2001 Acura Integra the ECU is found in the lower kickpanel on the passenger side footwell.

After you have the kick panel removed, then undo the 2 10 mm nuts holding the ECU Cover on. Then unbolt your ECU, pivot it toward you and start unplugging harnesses Remove your Emanage unit and the harness supplied. Lay it all out in front of you so for ease of install. Take the time to review this handy chart which shows you how to connect the Emanage to a MAP or pressure driven vehicle, like your Integra. First we start with the White Greddy wire, which for our car goes to the MAP input signal.

You will be splicing into this signal as you don’t want to rob the ECU of being able to see absolute manifold pressure. First step of the wiring process behind our How to Install a Greddy Emanage article is the MAP. Find the MAP input signal, wire D3 on our pinout. Cut this wire in half, connect the white wire to the sensor side of the harness. Then connect the Green Wire on the Greddy Emanage Harness to the other side of the MAP wire. The green wire is MAP output signal. Take the brown GReddy Emanage wire for RPM Signal and connect it to A20 on the ECU, which would be Ignition Control Module.

Emanage Solutions Canon

Take the red Greddy wire for power and connect it to A11 on the ECU, which would be ECU power on this P72 OBDII ECU. Then take the black Greddy wire for ground and connect it to A10 on the ECU which is Power Ground 1 Take the Yellow and light blue wires, which are VTEC output / input respectively. Find the A8 wire on the ECU which is the VTEC Solenoid wire and cut it in half.

Greddy E Manage Blue Software Download

Connect the Yellow wire to the sensor side of the harness, and connect the light blue wire to the ECU side of the harness Locate the VTEC Pressure Switch, pin C15 on the ECU pinout. Cut this wire in half and take the Purple VTM output wire on the Greddy loom and connect it to ECU side of wire C15 Now wrap everything up, and mount your Emanage somewhere safe and hidden away.

You can opt to tuck it up and behind your glovebox or try to squeeze it behind the passenger side kickpanel. There are quite a few versions of the Emanage in existence as we talked about at the beginning of our how to install a Greddy Emanage, including the Ultimate. Greddy Ultimate Emanage Jumper toggles Jumper No.

. ������������ ������. Table of Contents Table Of Contents 1. Important Information 2 3 2. Unit Description 4 5 3.

Initial Setup 6 9 4. How to Splice Wires 5. Harness Diagram 6. Wiring Power, Ground, Airflow Meter, Throttle, RPM signal 1213 7.

Important Information Please read this instruction manual carefully, and proceed with the installation ONLY if you fully understand this manual. Make sure to pay attention to all the 'Important!' And 'Caution!' Messages through out the manual.

This product is legal for sale or use in California only on vehicles which may never be driven on a public highway. Improper tuning of the e-Manage Ultimate can cause damage to the engine. GReddy Performance Products, Inc. Will not take any responsibility of damage caused by improper installation or tuning. Tuning should be performed only by a technician who fully understands the vehicle’s fuel management and ignition timing. Used with the Remote Switching System (sold separately) or Switching Harness (Sold separately). SERIAL.

Used to link the GReddy Warning Meters with a Data Link Cable (sold separately) OPTION1,2. Used to connect GReddy Pressure Sensor, GReddy Temp Sensor, and/or A/F Input Harness.

JP10 Airflow Signal Input 2 / VTEC Output GT-R RB26DETT VTEC OUT 1 - 2 JP11 OPTION 1 Normal GReddy Temp Sensor OPEN JP12 OPTION 2 Normal GReddy Temp Sensor OPEN JP13 Knock Signal Input 1 / Water Temp Input. Initial Setup Jumper Setting Description JP1 Injector Input / Output Signal CH1 This jumper will configure the Injector Input / Output Signal CH1. Set to “OPEN” when using Injector Adj. Map to trim and add fuel, and set to “1-2” to add only. JP2 Injector Input / Output Signal CH2 This jumper will configure the Injector Input / Output Signal CH2. OPTION 1 This jumper will configure the OPTION 1 port on the Front Panel of the unit. Set to “OPEN” for Normal type(when used for pressure or A/F sensor), and “1-2” when using GReddy Temp Sensor.

JP12 OPTION 2 This jumper will configure the OPTION 2 port on the Front Panel of the unit. Initial Setup Jumper Location When Jumping “1-2” or “2-3” make sure to match the pin numbers printed on the circuit board at the coresponding jumper locations. For “OPEN” make sure the jumper is not jumping the pins at the corresponding jumper locations. How to splice wires 1.Strip the wire as shown.

2.Wrap the stripped wire together as shown, and set the crimp in place.Crimp is not neccessary if soldering. 4.wrap the connection with shrink tube or 3.Crimp or solder the connection. Electrical tape.